Custom A.S.M.E. Code Tank Manufacturing and Fabrication

The Halvorsen Company Fabricates Custom ASME Code Compliant Pressure Vessels, Heavy Duty Pressure Retaining Parts, Shells, Cylinders, Cones, Components and Tanks

- Call 1-800-423-7080 for a Quote

- To Submit an RFQ, CAD Drawing or P.O. Email sales@halvorsenusa.com

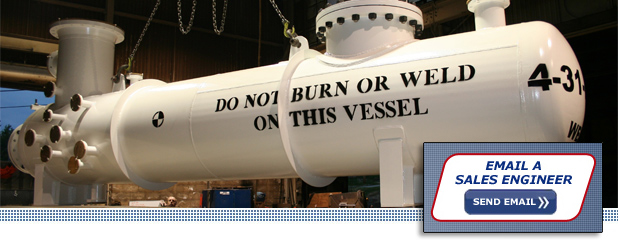

Halvorsen Company provides custom A.S.M.E. and A.P.I. code certified tank and pressure vessel manufacturing and fabrication services. We are one of the most trusted producers and suppliers of large, built-to-order, high quality pressurized tanks, process tanks and pressure vessels in the United States. Our steel fabrication business and production facilities are located in Cleveland, Ohio. Halvorsen specializes in the design, engineering, and fabrication of custom ASME code tanks.

To talk with us about our custom A.S.M.E. code tank manufacturing and fabricating capabilities please call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.

We are the leading ASME code tank and code vessel supplier in the Midwest portion of the United States. We are capable of manufacturing code tanks and A.S.M.E. code tanks from carbon steel and alloy steel up to 100 tons.

We are fabricators and manufacturers of custom and standard ASME (American Society of Mechanical Engineers) Code and Non-Code tanks, pressure vessels and components. We build closed containers that are designed to hold gases or liquids at a pressure substantially different from the ambient pressure. We are a custom fabricator of steel and alloy steel tank shells, separators, columns, heat exchangers, chambers, bladders, boiler steam drums, hydraulic and pneumatic accumulators, settler vessels, pulp and paper steaming vessels, pressurized storage tanks, cooker vessels (jacketed steam-cooker vessels), stripper columns and towers, vertical water softener vessels, pressure reactors, ASME separators, specialized heat exchangers, distillation towers, oil and gas refinery pressure vessels, flash tanks, rubber lined tanks, blow down tanks, compressed air vessels, mixing tanks, filter tanks, cyclone separators, autoclaves, API 650 units and deaerators.

We build code tanks and A.S.M.E. code tanks for applications such as food processing, oil and gas refining, chemical and petrochemical manufacturing, fertilizer mixing, pharmaceutical manufacturing, biotech, air & gas compression, adhesive manufacturing and paper processing industries.

When Halvorsen Company manufactures a tank or pressure vessel per the guidelines of ASME’s International Boiler and Pressure Vessel Code, the product is reviewed multiple times by certified inspectors. When we fabricate code tanks and code vessels we use pressure vessel-rated, parts and materials. We thoroughly review our calculations to verify the design requirements for cone stress, flanged dish heads, torispherical head walls and circumferential shells and ellipsoidal heads under internal pressure and many other components. Before we ship our code tanks, code vessels or pressure vessels to an oil refinery, chemical plant or manufacturing company, we conduct nondestructive examinations and tests.

Click here to download the ASME Boiler and Pressure Vessel Code with Addenda. The ASME Boiler and Pressure Vessel Code (BPVC) establishes rules of safety governing the design, fabrication, and inspection of boilers and pressure vessels and nuclear power plant components during construction.

To submit a design or CAD drawing of a code tank, request a quote for fabrication of a code tank, to submit an RFQ, ask a sales engineer a question, discuss your current project, place a fabrication order, submit a P.O. (purchase order) or to schedule a tour of our facilities, please call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.