Steel Fabrication Testing, Inspection and Metallurgical Services

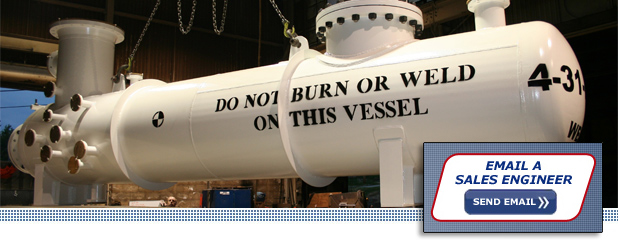

The Halvorsen Company provides testing, inspection and metallurgical services in conjunction with our heavy steel plate and fabrication services and ASME code pressure vessel construction services.

We operate a Quality Control and Assurance Program which is a key component of our testing and inspection services. We have Level II P.T. (Liquid Penetrant Testing) and M.T. (Magnetic Particle Testing) certified inspectors on staff full time.

The Halvorsen Company uses wide array of non-destructive testing and inspection techniques including Magnetic Particle (MT), Dye Penetrant (PT), Radiography (RT) and Ultrasonic (UT).

As an ASME-compliant steel fabrication and pressure vessel manufacturing company, we utilize visual inspections along with 100% fit-up and 100% final weld inspections. During our final inspections, we double check all our welds and perform numerous dimensional inspections. We are well respected in the industry for the testing and inspecting that we perform during the fabrication and manufacturing of boiler components, heat exchangers, process tanks and ASME pressure vessels.

Our experienced engineers and skilled craftsman understand the technology and science of metallic materials, heavy steel plate, and alloy steel plate. Our metallurgists and engineers provide a high level of expertise in the fabrication of steel and alloy plates, heavy steel segments, boiler components, ASME pressure vessels, steel and alloy sections, and rolled and welded cylinders and cones. We possess a detailed knowledge of the adaptations, applications in use and performance in service of metallic materials and heavy steel and alloy plate. Our staff specializes in metallurgy specifically for the forming and heat treating processes of heavy steel plate fabrications, which are used in rolled and welded assemblies.

Since 1955, we have been providing heavy steel fabrication capabilities and heat treatment capabilities for heavy wall rolled and welded cylinders (both code and non-code), hot rolled heavy sections, forgings, castings and heavy pipe. We provide metallurgical services for the material selection, fabrication and heat treatment of fossil fired boiler components and pressure vessels used for steam and power generation. We understand ASME Section II materials and work closely with sub-let fabricators of ASME Section I parts and components.

Our inspectors, testing staff and metallurgists are experienced in corrosion control, corrosion engineering evaluations, pressure vessel material selection, boiler component material selection, risk based inspections, failure analysis and heavy steel product development.

We provide testing services, inspection services and metallurgical services to a variety of industrial customers such as chemical plants, steel mills, oil and gas refineries, petrochemical facilities, pulp and paper mills, power generation plants and other industrial facilities.

Recognition and Auditing:

Our quality systems are recognized and audited by the American Society of Mechanical Engineers (ASME). We hold ASME code construction certificates as follows; “U” Certificate # 3415, “S” Certificate # 3470 and “H” Certificate # 21,019. We are also a holder of the National Board “R” Certificate # 2613. The Halvorsen Company has maintained these certificates on a continuous basis since 1955.

Our Quality Manager is Rudy Ramic. For information about our program, please contact him using the information listed below.

Contact Our Quality Manager, Rudy Ramic:

Toll Free: 1-800-423-7080, extension 214

Direct Line: 216-706-2210

Email: rramic@halvorsenusa.com

Direct Fax Line: 216-706-2211

Our Quality Control and Assurance Program complies with the following:

- AWSD 1.1 compliant

- ISO 9000 compliant

- API 650 compliant

We have on-staff AWS CWI (Certified Welding Inspector) inspectors and in-house level II MT, PT inspectors. We have third party contract services for RT, UT inspections. Other quality functions include First Article Inspections with documentation, spot or random inspections, 100% dimensional inspections, MTR verification and review and others as requested by our customers.

Specialty Testing, Inspection and Quality Control Equipment:

- FARO Arm Platinum 12′ CMM

- 80” VersaGage

- 2 Calibrated Granite Inspection Tables

- Multiple Layout Tables up to 16′ x 32′

Learn More:

To talk to us about our testing, inspection and metallurgical services, or to get a quote, call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.

We provide testing, inspection and metallurgical services for the following parts, equipment, products, applications and components:

- Fired and Unfired ASME Code Pressure Vessel Components

- Boiler Components

- Rings

- Gear Blanks

- Process Tanks

- Storage Tanks

- Steam Drums

- Heavy Weldments

- Flash and Blowdown Tanks

- Ladles

- Platework

- Custom Heat Exchangers

- Steel Shells

- Ammonia Tanks

- Cones

- Cylinders

- Furnaces

- Steel Casings

- Cylindrical Shapes

- Deaerators

- Heavy Wall Large Pipe and Piping

- Other heavy industry and steel industry components and products.

To learn more about our testing, inspection and metallurgical services, to submit a design or CAD drawing, request a quote or submit an RFQ, ask a sales engineer a question, discuss your current project, place a fabrication order or to schedule a tour of our facilities, please call 1-800-423-7080 and ask for Justin Frick or a Sales Engineer or email sales@halvorsenusa.com.